People in general are always looking for ways to improve the things we do every day by making them easier and more efficient...today's technology makes this possible. From online shopping, to FaceTiming a friend halfway across the world, advancements in technology impact nearly every aspect of our lives. Technology has also affected manufacturing in ways that were unthinkable just 20 years ago!

At Scotchman, we want to help your shop efficiently produce the best cuts possible with automatic and semi-automatic machines like our circular cold saws and measuring systems.

Not sure if adding automation is worth it? We’re giving you four benefits of adding automation to your factory and your sawing processes to explain how adding small bits of technology can improve your everyday processes.

1. Decrease Operator Error and Fatigue

Even the very best machine operators make mistakes once in a while. Adding programmable automation to a circular cold saw allows you to program your cut list, giving you a precise cut every single time.

Adding automation systems can also reduce operator fatigue, increase production speed, and free up skilled labor for more complex tasks. Your time and your machine operator's time is of great value.

Read a recent customer review on our CPO 350 PKPD with added automation.

2. Increase Profits & Save Time with Sawing Automation

Do you want to increase profits? Of course you do! Automation can help you achieve it.

By incorporating semi-automatic or fully automatic cold saws and measuring systems into your shop, you’ll be able to produce more quality parts in less time. As efficiency and production go up, you’ll notice a rise in profits.

After making the initial investment, automation systems will save you time and money...AND BONUS... you won't have give them a paid coffee break!

3. Semi-Automatic and Fully Automatic Machines Prove Easy to Operate

Even though learning new technology gives some of us a bit of anxiety, it really isn’t as scary as you might think.

Before turning to fully automatic machines, you may find it helpful to begin by incorporating semi-automatic cold saws and measuring systems into your facility. Start by having a computer measure your part lengths instead of a tape measure and a chalk pen.

Scotchman’s SUP-600 NF Upcut cold saw has been coupled with AngleMaster technology and is proven to be an effective production saw for many industries, especially the aluminum extrusion market.

At the push of a button, this semi-automatic programmable saw system will automatically rotate to any cut angle, push the material into the saw, and then rotate to the next desired angle.

If your shop or factory is already utilizing semi-automatic saws, consider going fully automatic!

Why go fully automatic? Flexibility, efficiency, and accuracy are all maximized with fully automatic machines. After implementing a full-auto saw, you’ll notice an immediate impact on your business and see an increase in production with greater accuracy.

4. Automation and Machine Operators Work Well Together

The fear that many people have about adding automation is that it will take jobs away from factory employees.

The truth is, as technology develops, the need for skilled employees will become greater, not less. With technology comes new discoveries and new opportunities. Adding automation to your factory will not force you to lay off your dedicated employees.

If anything, the skills for which you hire may evolve. This is okay, and shows that you are a progressive business, looking ahead to the future to make your company the best it can be. Read more on how automation won't kill jobs, but help them evolve into better jobs in this article by the IEEE Institute.

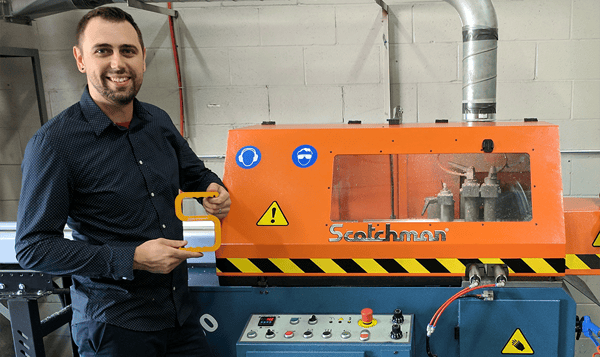

Read how our customer, Motis, brought his manufacturing processes back in-house.

Choose Scotchman for Your Sawing Automation Needs

Could your business benefit from the increased accuracy, efficiency, and profitability that come with incorporating automated cold saws and measuring systems? Download our Measuring, Stop, and Feed Systems flyer and our Sawing Automation flyer to learn more about our automated products.

At Scotchman, we embrace technology. We’re constantly researching and working to produce the most cost-effective and efficient machines in the metal fabrication industry that will help your business achieve its goals. When you succeed, we've done our job!

.jpg)