More Versatility and Flexibility than Any Other Ironworker on the Market!

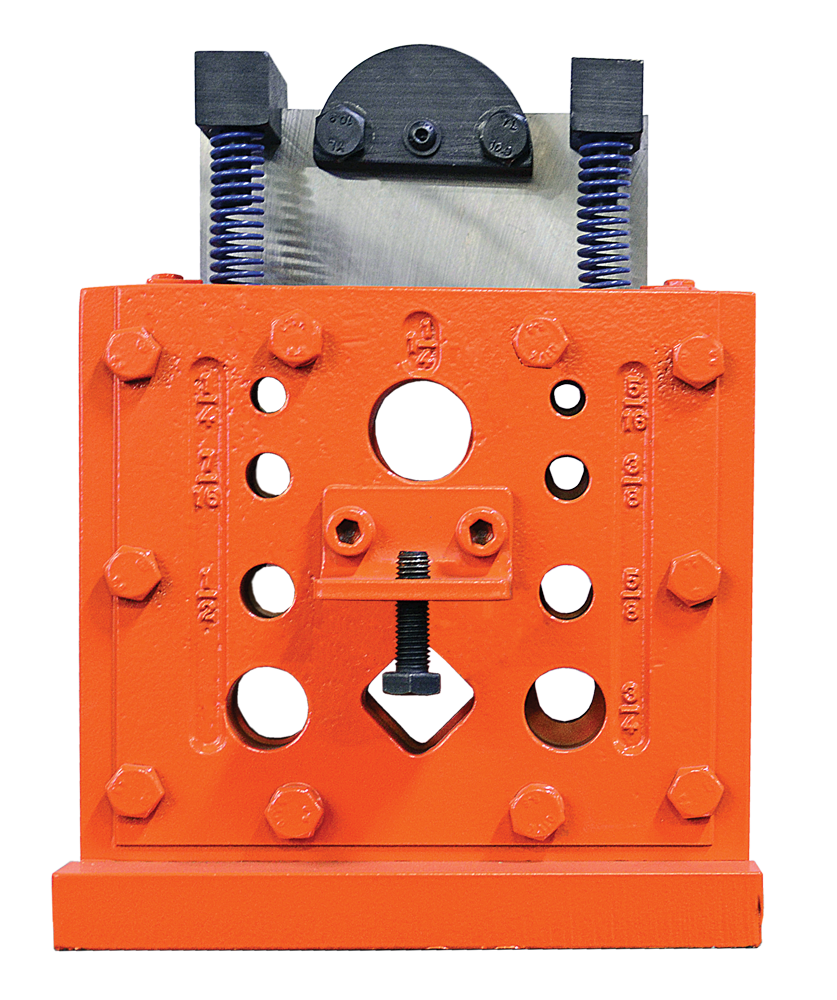

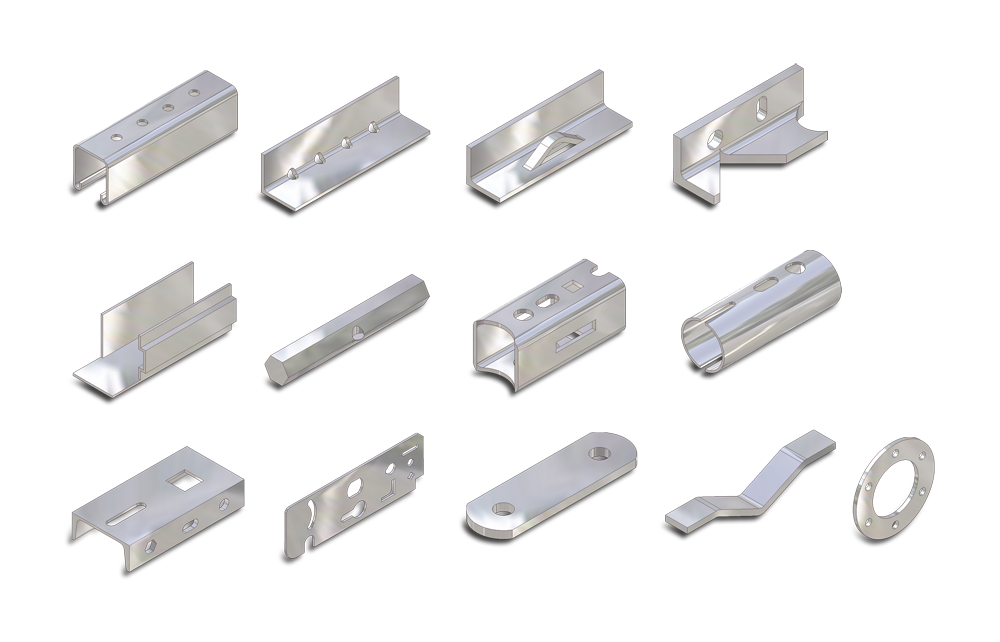

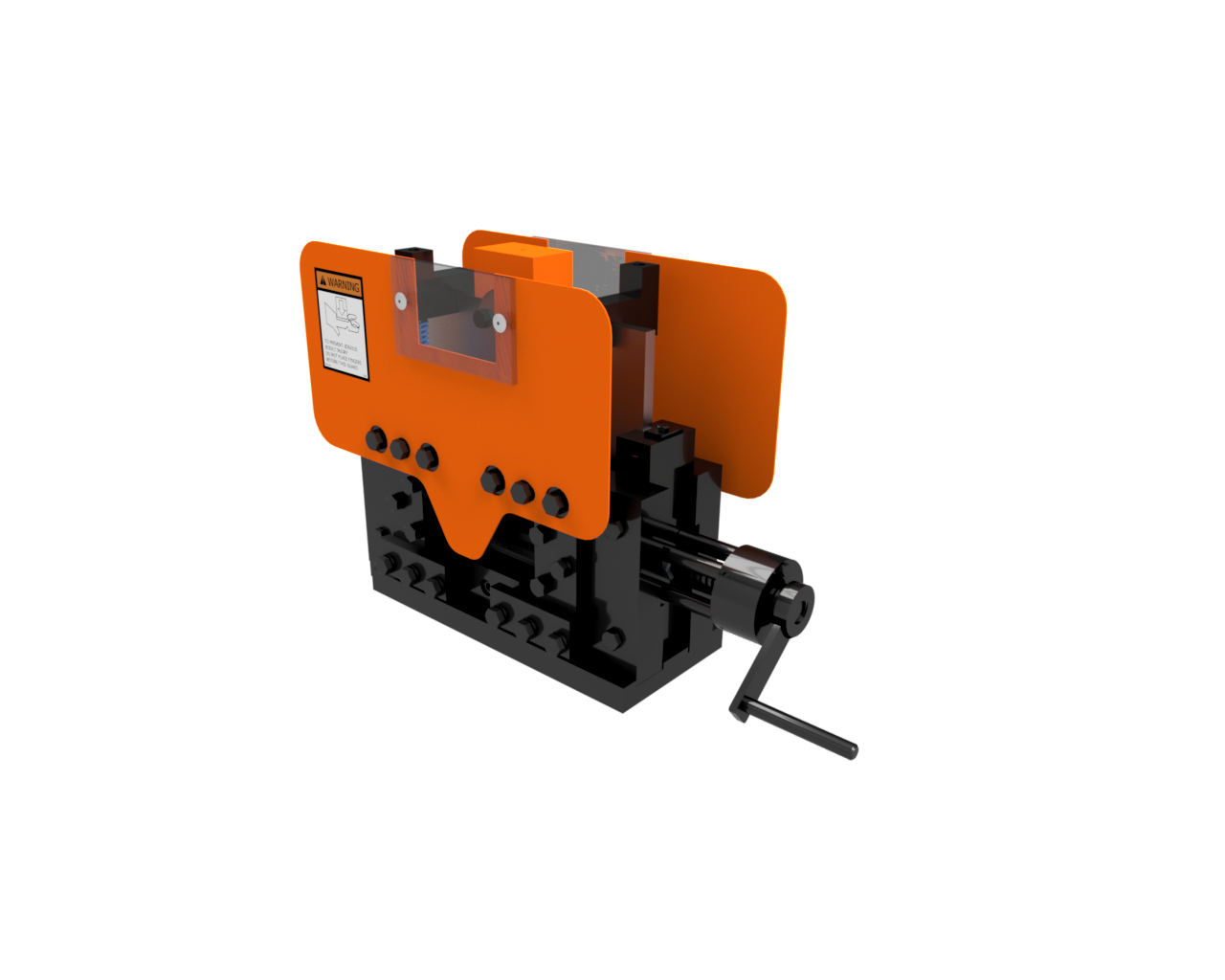

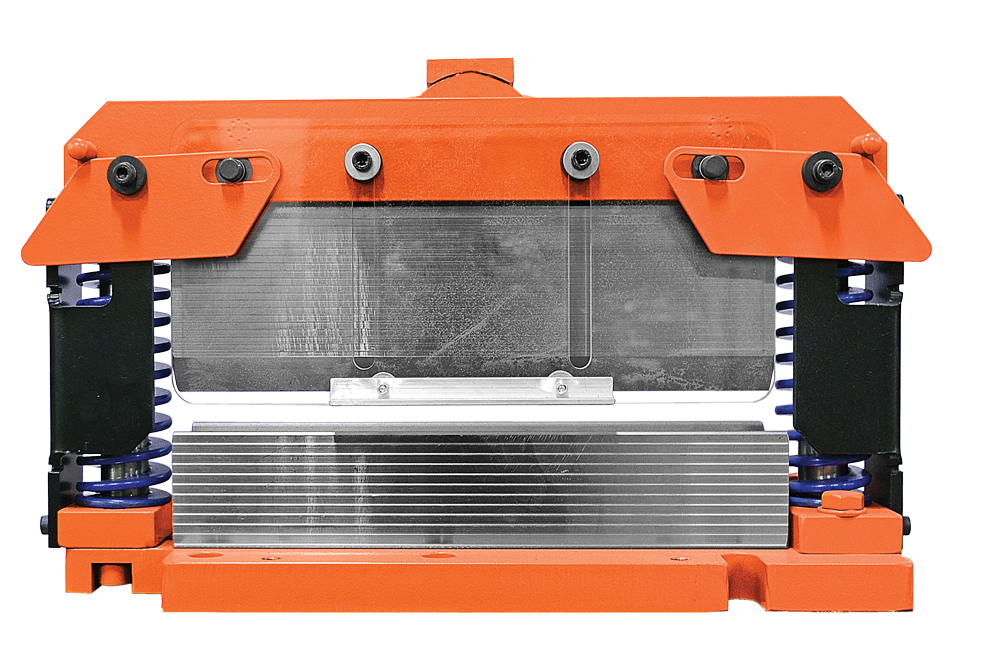

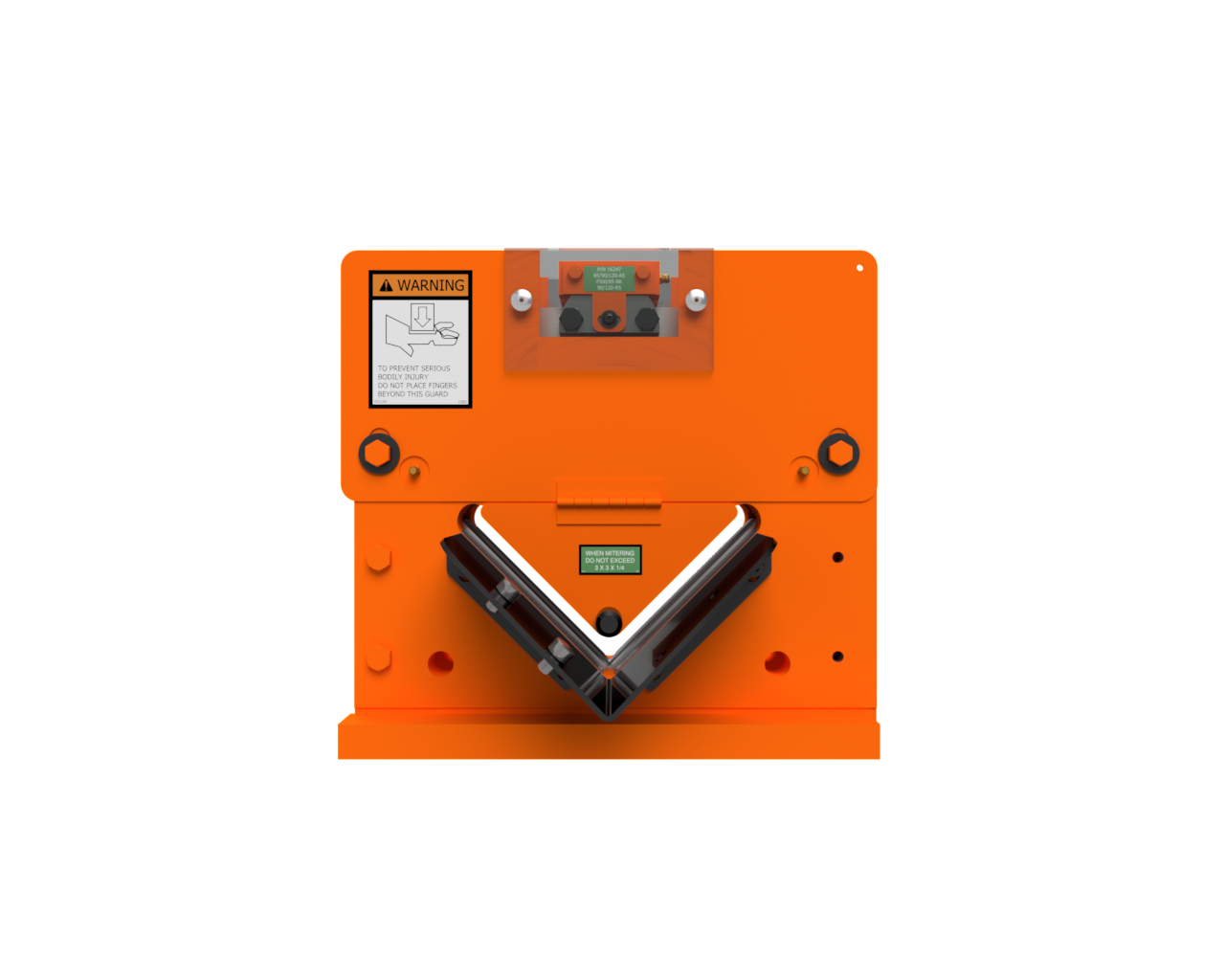

With a 65-ton punching capacity, this ironworker can punch 1-1/16" hole through 3/4" thick, 65,000 tensile plate. It has the largest flat bar shear capacity and the largest angle shear capacity of any machine in its class. Combining this machine's large capacity with its large open tool table makes this machine the most versatile and flexible machine on the market.

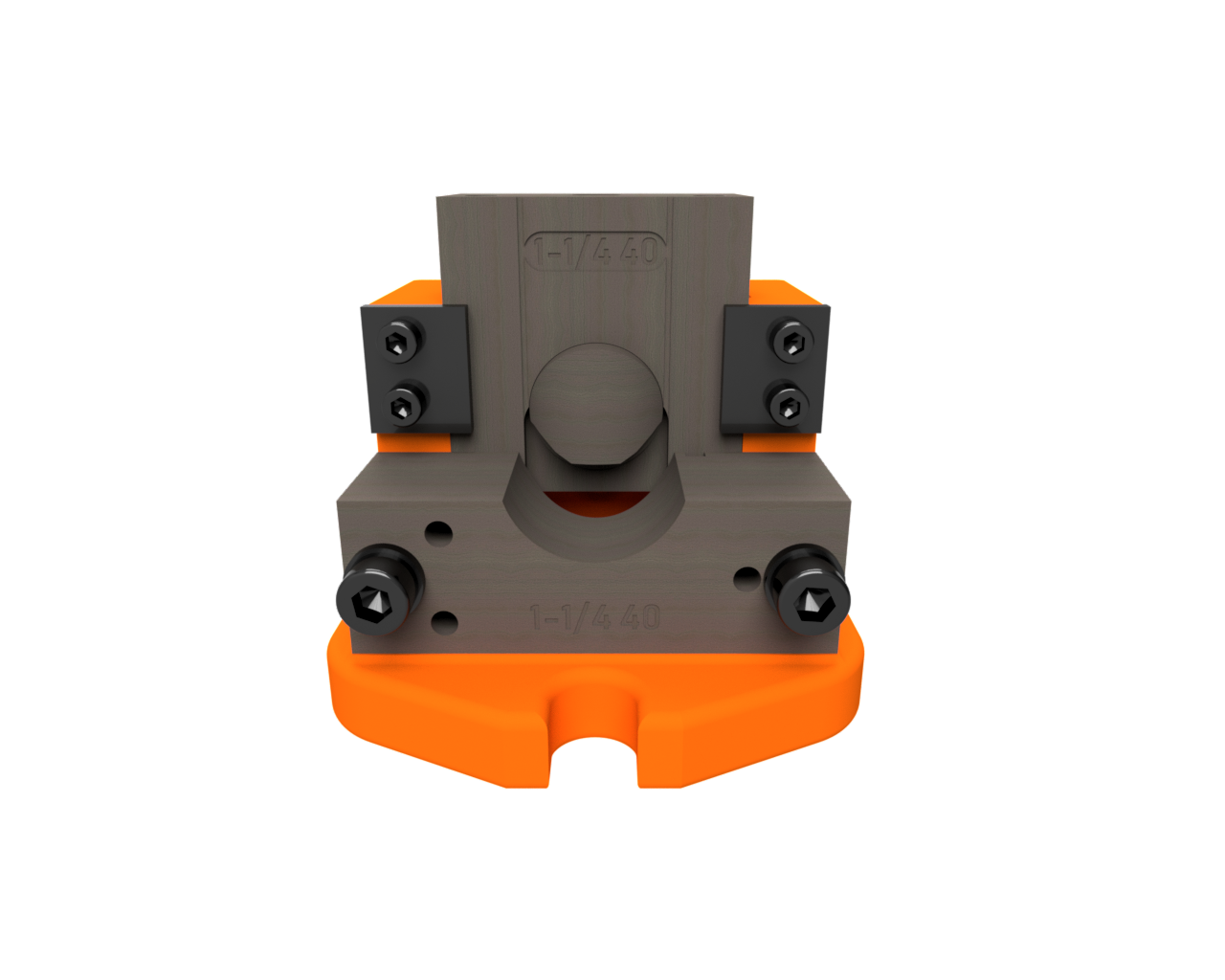

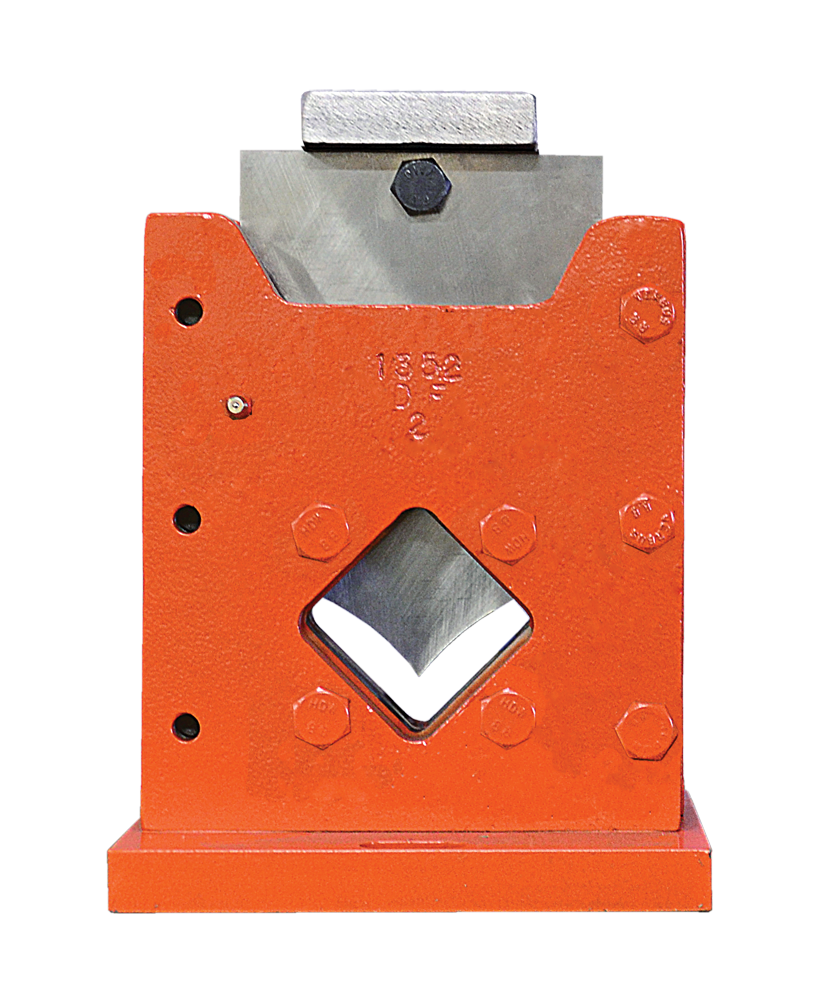

A six inch angle shear comes standard and is located in our unique tool table area. This versatile workstation allows additional tooling to be quickly & easily swapped in and out so you can customize the machine to fit your needs.

This American-made ironworker is built tough and utilizes a hydraulic system with electric valve & remote foot pedal for ease of use, an adjustable electric stroke control with scale, and is backed by Scotchman’s industry leading 3-Year Warranty and lifetime customer support!

.jpg)

.png)