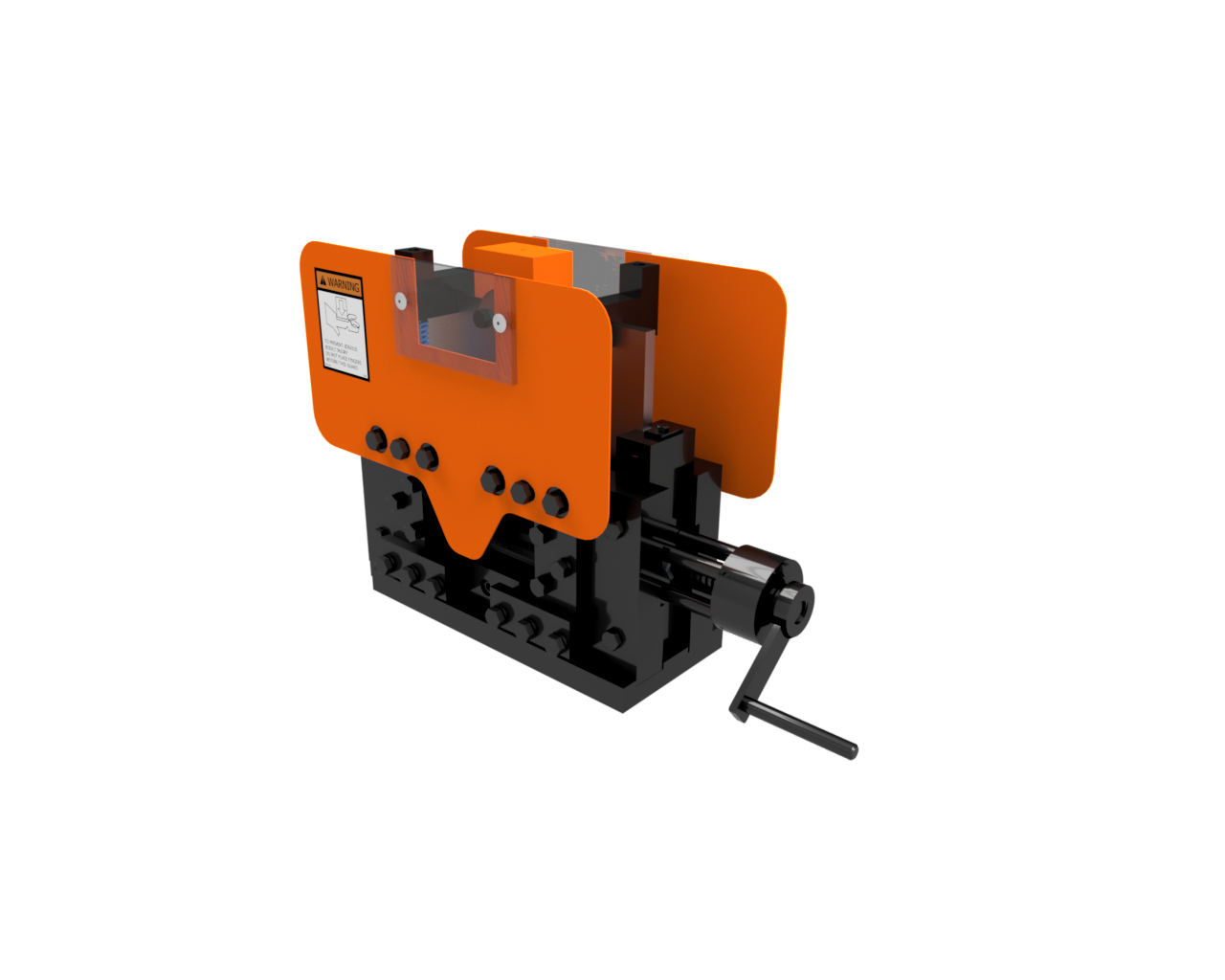

When two operations are required to run simultaneously like punching and notching, a dual-operator ironworker is often the best solution.

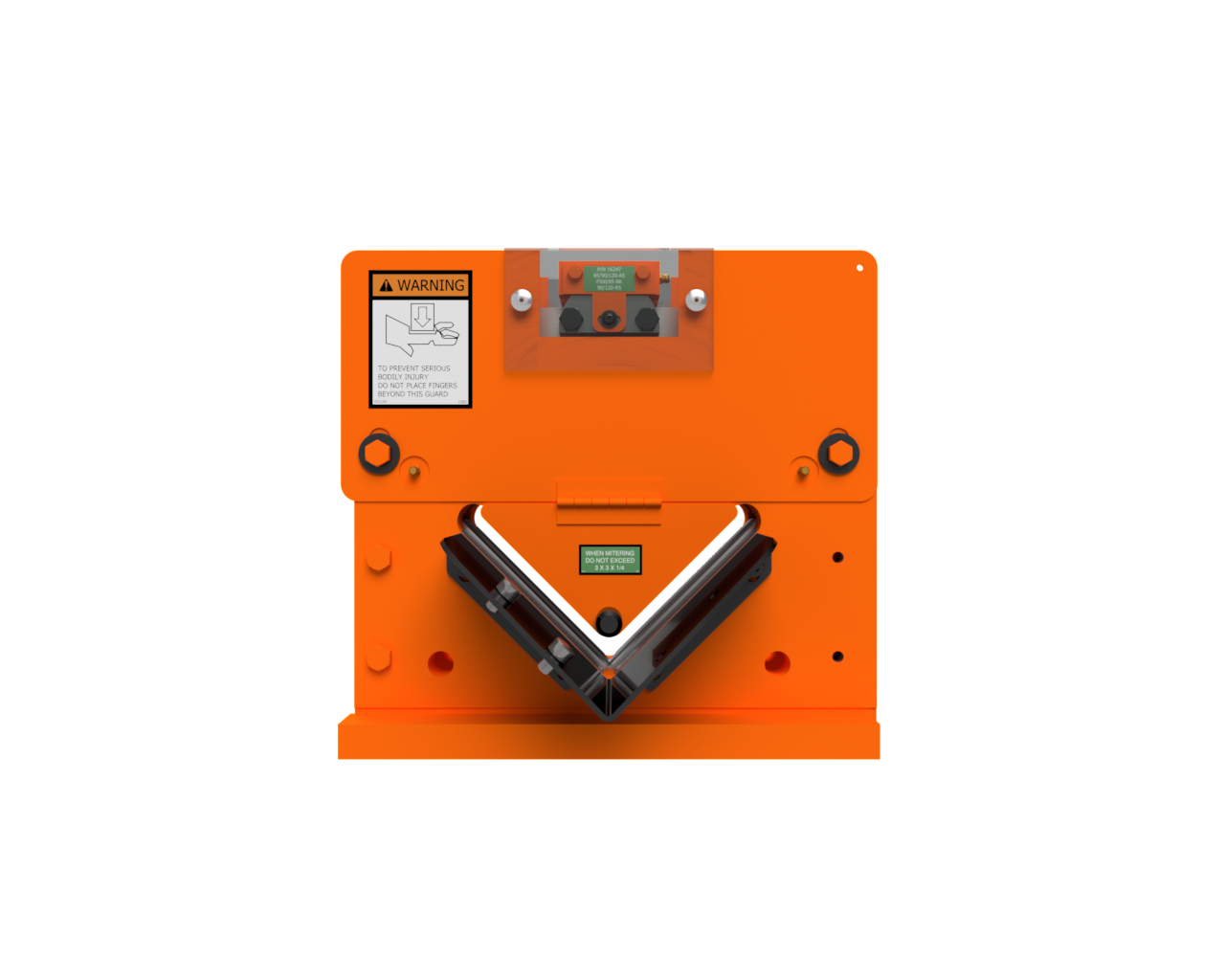

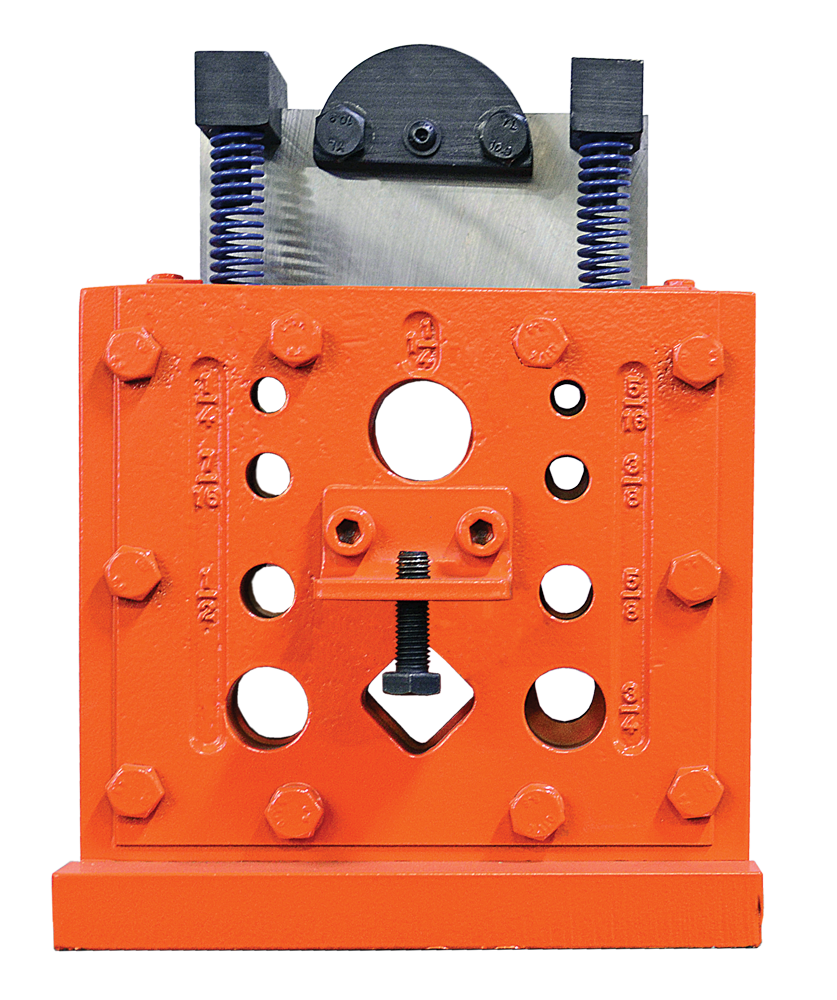

The dual operator 120-ton ironworker machine has a tandem hydraulic pump system designed to allow two operators to use the machine at the same time ensuring that both operations will have full hydraulic pressure and speed.

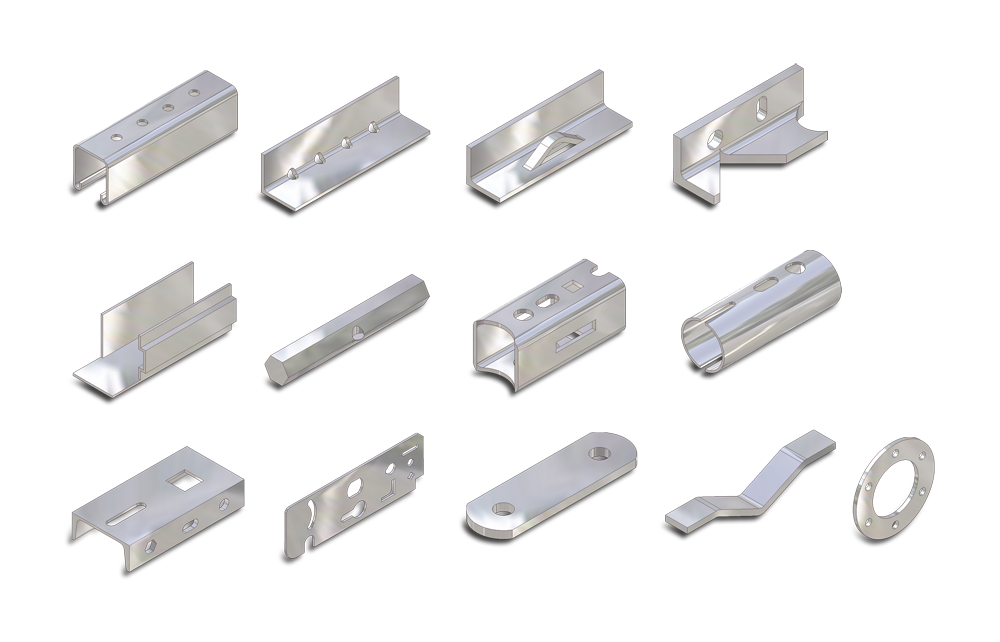

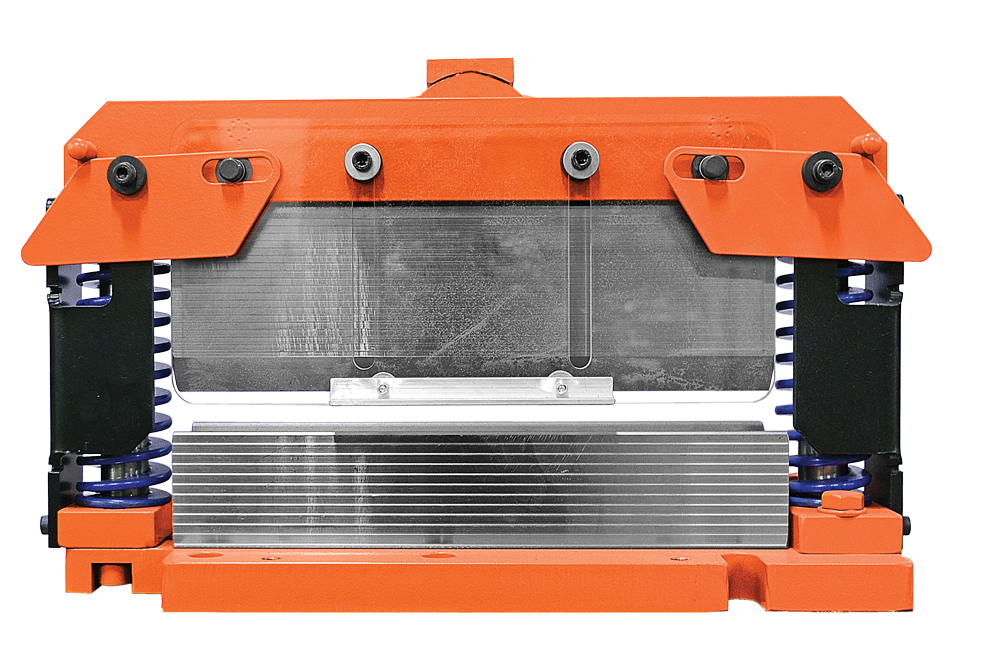

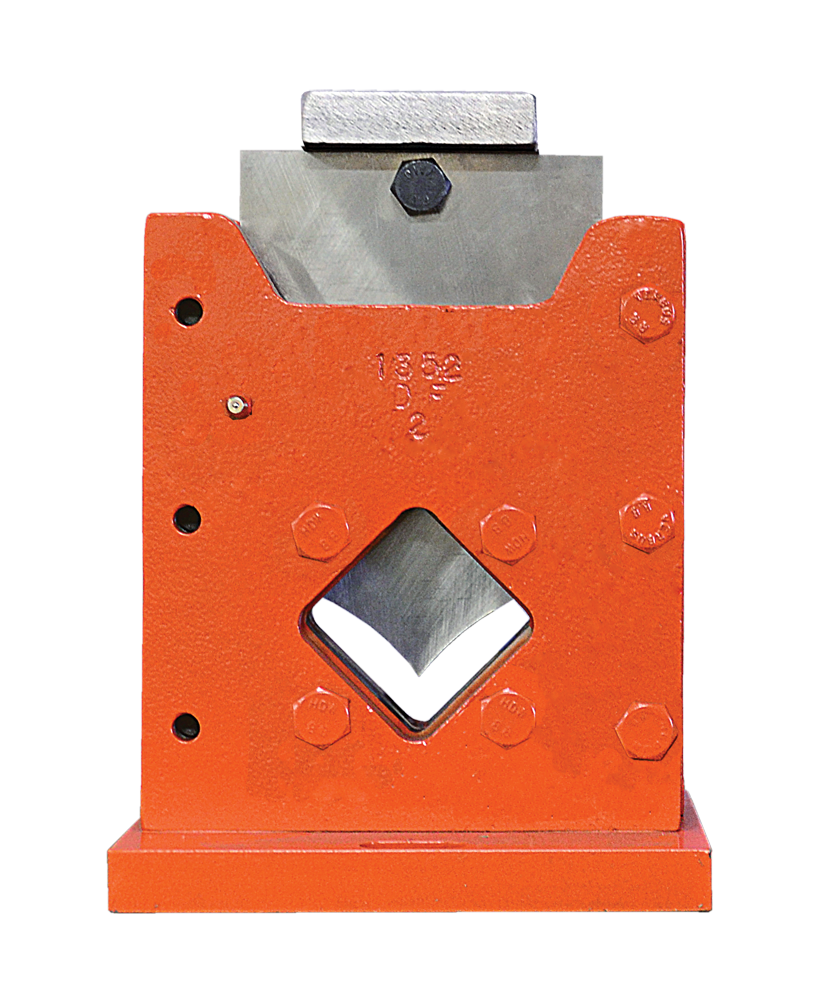

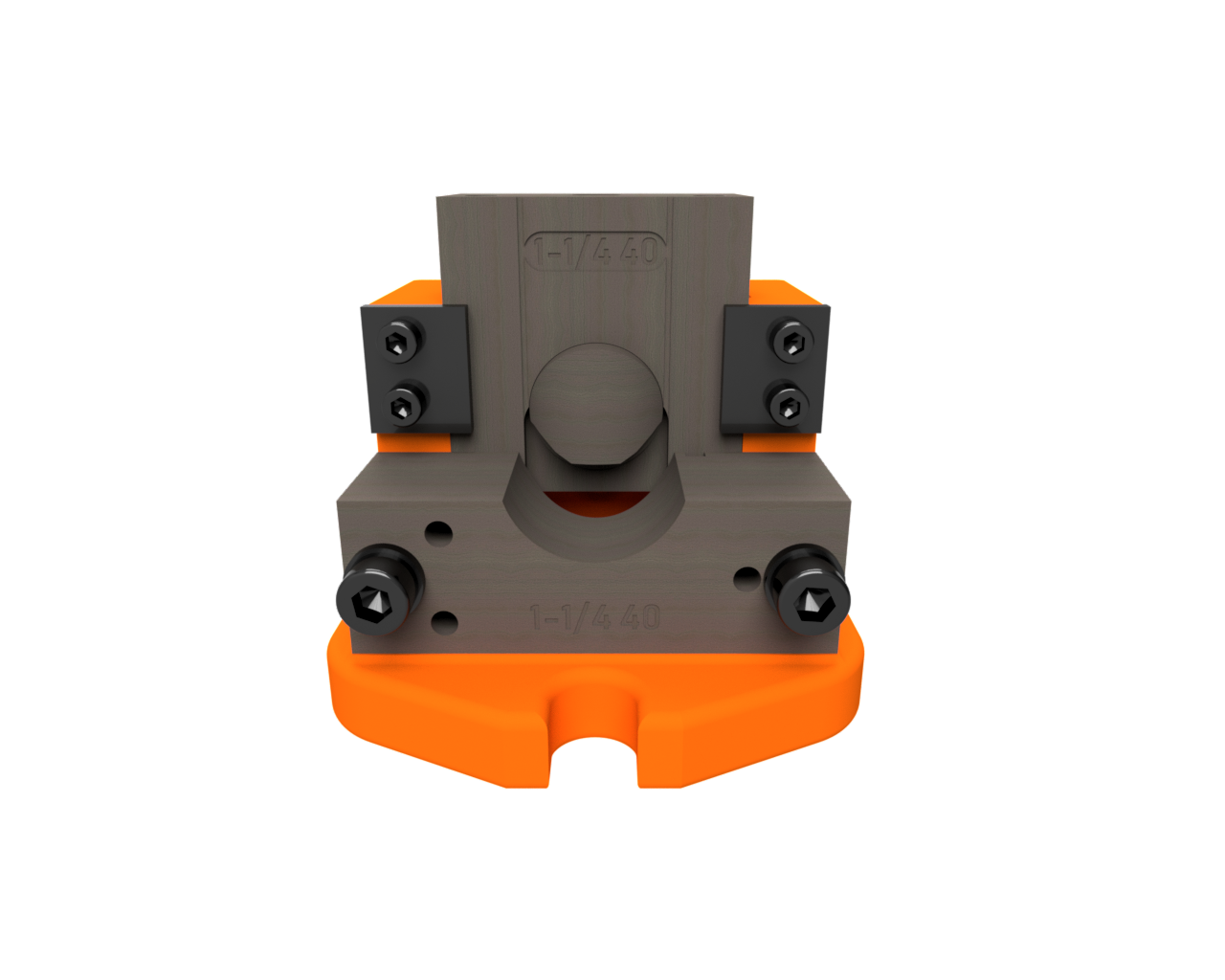

The DO120 has a 120-ton capacity punch and a 12" throat depth, which can punch a 1-1/2" hole in 1" thick mild steel. The DO 120/200-24M is made in America with many standard features that include: 6" x 6" x 1/2" angle shear and a rectangular notcher that can notch 3" x 5" through 3/4" material. The 24" flat bar shear features a low rake angle and can shear up to 1" x 6" and 1/2" x 24" steel plate. This versatile ironworker allows additional tooling to be easily swapped in and out so you can customize the machine to fit your needs!

This American-made ironworker is built tough and utilizes a hydraulic system with electric valves & remote foot pedals for ease of use, an adjustable electric stroke control with scale, and is backed by Scotchman’s industry leading 3-Year Warranty and lifetime customer support!

.jpg)

.png)

.png)

.png)

-min%20(1)%20FINAL2.png)